Structured Point Clouds

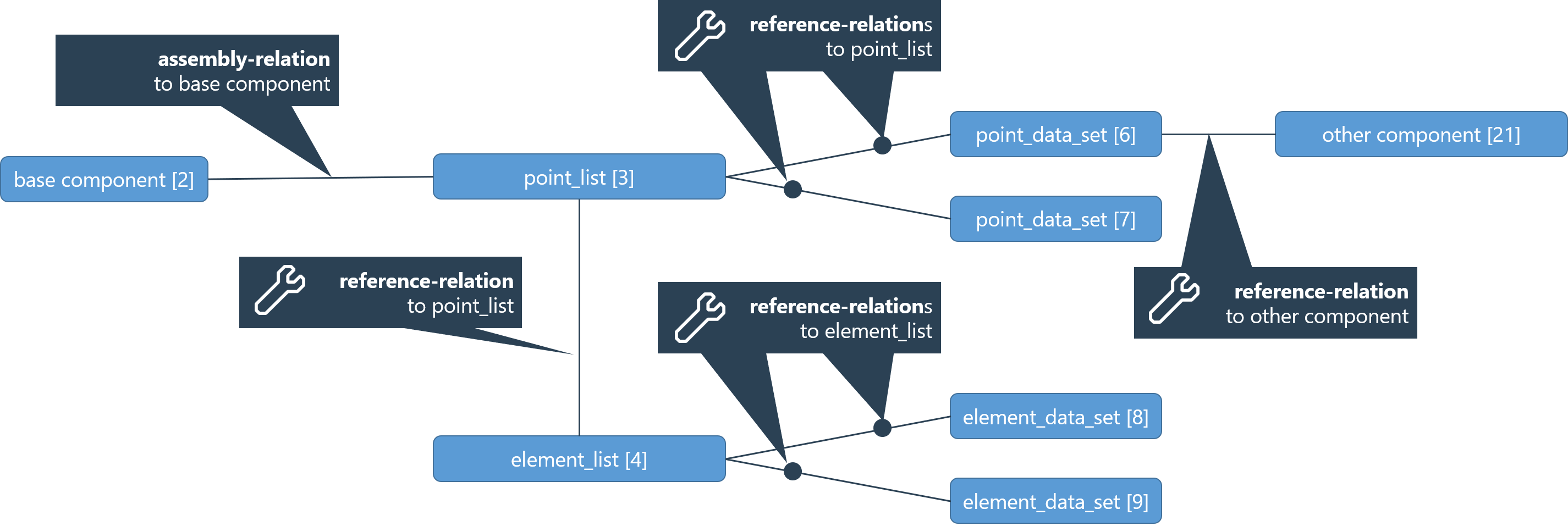

Structured point clouds (e.g., FE data, 2D & 3D gear geometries, etc.) can be directly modeled in REXS. A generic concept was developed for this purpose, which differentiates between points, element structures, and associated data (e.g., stresses).

Point lists | point_list

The point list component (point_list) includes a list of node IDs and a list of point coordinates. The type of point list can also be specified (e.g., "FE mesh" or "contour of the finished gear").

The point list is linked with the associated base component via an assembly relation. The point coordinates are always relative to the coordinate system of the base component. If this component does not have its own coordinate system, the coordinate system of the associated parent component is used.

The possible base components for a point list and the corresponding coordinate system are explicitly defined below for each application.

Required relations | XML syntax |

|---|---|

Assembly relation | <relationid="45"type="assembly">

<refid="30"role="assembly" hint="base component"/>

<refid="31"role="part"hint="point_list"/>

</relation> |

Element lists | element_list

The points of a point list can be structured via one or more element lists. The IDs of the associated points for each element are stored in a list. The element list component (element_list) includes a list of element IDs, a list of associated element types, and an associated list of point ID lists.

Example XML syntax

<attribute id="element_ids" unit="none"> <array> <c>1</c> <c>2</c> <c>3</c> <c>...</c> </array> </attribute> <attribute id="element_type" unit="none"> <array> <c>quad4</c> <c>quad4</c> <c>triangle3</c> <c>...</c> </array> </attribute> <attribute id="element_structure" unit="none"> <array_of_arrays> <array><c>108</c><c>2</c><c>1</c><c>107</c></array> <array><c>109</c><c>3</c><c>2</c><c>108</c></array> <array><c>8</c><c>114</c><c>115</c></array> <array><c>...</c></array> </array_of_arrays> </attribute>

The element list is linked with the associated point list via a reference relation.

Required relations | XML syntax |

|---|---|

Assembly relation | <relationid="45"type="reference">

<refid="30"role="origin"hint="point_list"/>

<refid="31"role="referenced"hint="element_list"/>

</relation> |

*_data_set components

Depending on the application, point or element list-specific *_data_set components can be assigned (e.g., gear_flank_data_set).

In addition to application-specific result variables, each *_data_set component includes a list of associated point or element IDs. This can be any subset of the associated IDs.

A *_data_set component is linked with the associated point or element lists via a reference relation.

Required relations | XML syntax |

|---|---|

Reference relation | <relation id="45" type="reference" > <ref id="30" role="origin" hint="point_list"/> <ref id="31" role="referenced" hint="point_data_set"/> </relation> |

Reference relation | <relation id="46" type="reference"> <ref id="31" role="origin" hint="element_list"/> <ref id="35" role="referenced" hint="element_data_set"/> </relation> |

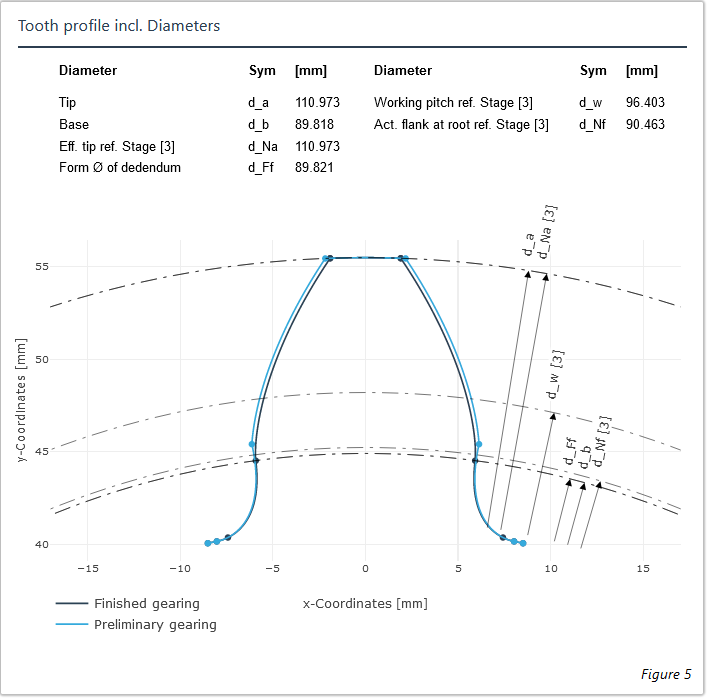

Use case: tooth contour

The tooth contour of a cylindrical gear can be modeled in REXS as follows: The point list is assigned to the cylindrical gear/ring gear via an assembly relation. The point coordinates refer to the coordinate system of the gear. Accordingly, for a contour in transverse section, all points in the list should have the same u-coordinate. Optionally, a point list can be used to structure the points. Otherwise, the order of the points in the list is used.

Required components | XML syntax |

|---|---|

Cylindrical gear | <component id="4" type="cylindrical_gear"> ... </component> |

Point list | <component id="8" type="point_list"> ... </component> |

Optional components | XML syntax |

|---|---|

Element list (if desired) | <component id="9" type="element_list"> ... </component> |

Required relations | XML syntax |

|---|---|

Assembly relation | <relation id="9" type="assembly"> <ref id="4" role="assembly" hint="cylindrical_gear"/> <ref id="10" role="part" hint="point_list"/> </relation> |

Reference relation (if an element list is used) | <relation id="12" type="reference"> <ref id="12" role="origin" hint="point_list"/> <ref id="8" role="referenced" hint="element_list"/> </relation> |

The kind_of_point_list attribute can be used to specify whether the contour is of the finished or preliminary gear.

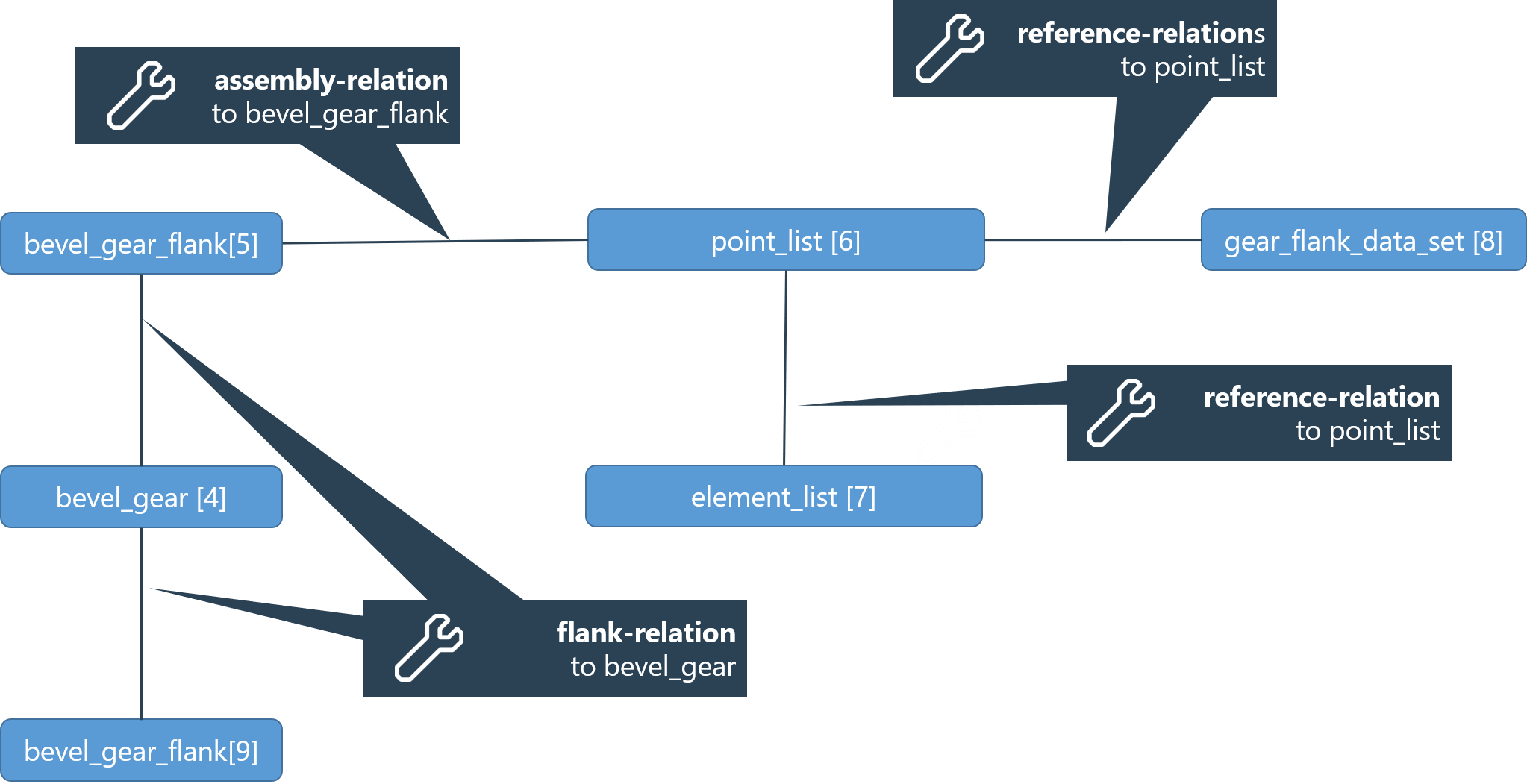

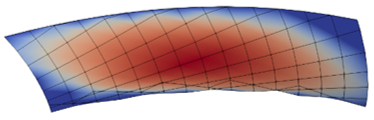

Use case: 3D tooth flank geometry

3D point clouds can be used to describe tooth flank geometry as follows: The point list is assigned to a tooth flank component (*_gear__flank) via an assembly relation. The point coordinates are relative to the coordinate system of the associated gear. An element list and a flank data component (gear_flank_data_set) are assigned to the point list via reference relations. The point list can be identified as a tooth flank mesh via the kind_of_point_list attribute.

The point coordinates can describe both nominal and actual geometry. The associated topographic deviations can be defined in the flank data component.

Required components | XML syntax |

|---|---|

Gear flank | <component id="5" type="*_gear_flank"> ... </component> |

Point list | <component id="6" type="point_list"> ... </component> |

Element list | <component id="7" type="element_list"> ... </component> |

Flank data | <component id="8" type="gear_flank_data_set"> ... </component> |

Required relations | XML syntax |

|---|---|

Assembly relation | <relation id="9" type="assembly"> <ref id="5" role="assembly" hint="*_gear_flank"/> <ref id="6" role="part" hint="point_list"/> </relation> |

Reference relation | <relation id="10" type="reference"> <ref id="6" role="origin" hint="point_list"/> <ref id="7" role="referenced" hint="element_list"/> </relation> |

Reference relation | <relation id="11" type="reference"> <ref id="6" role="origin" hint="point_list"/> <ref id="8" role="referenced" hint="gear_flank_data_set"/> </relation> |

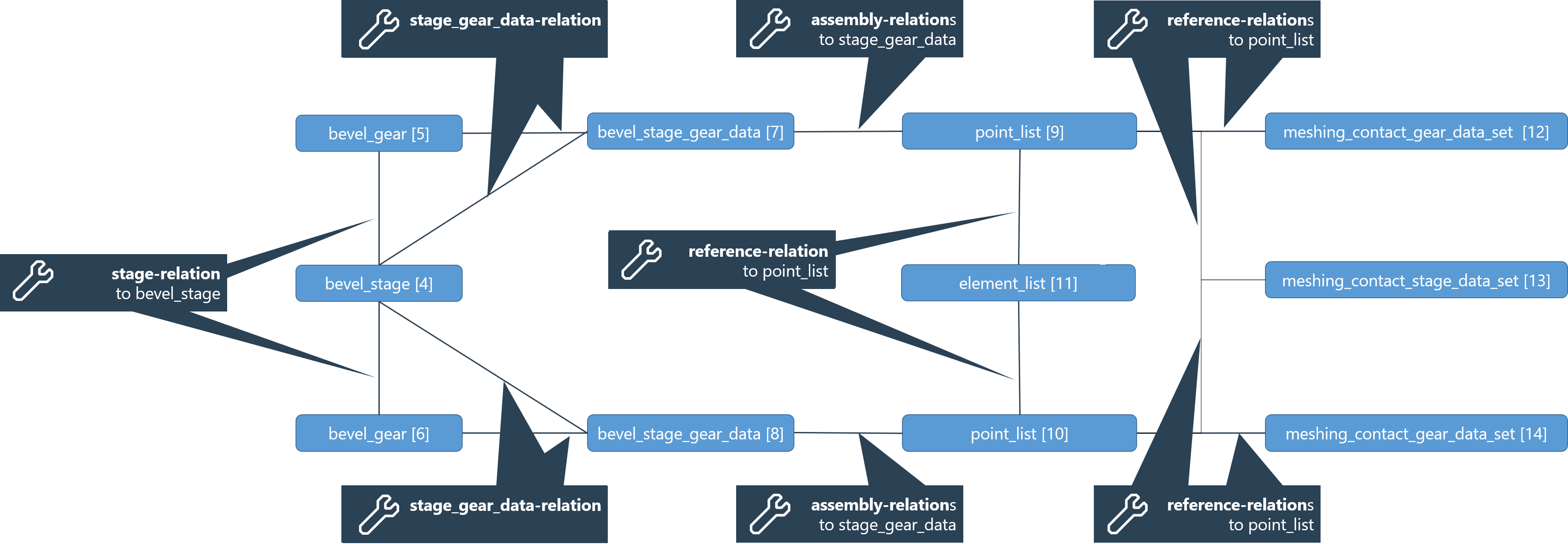

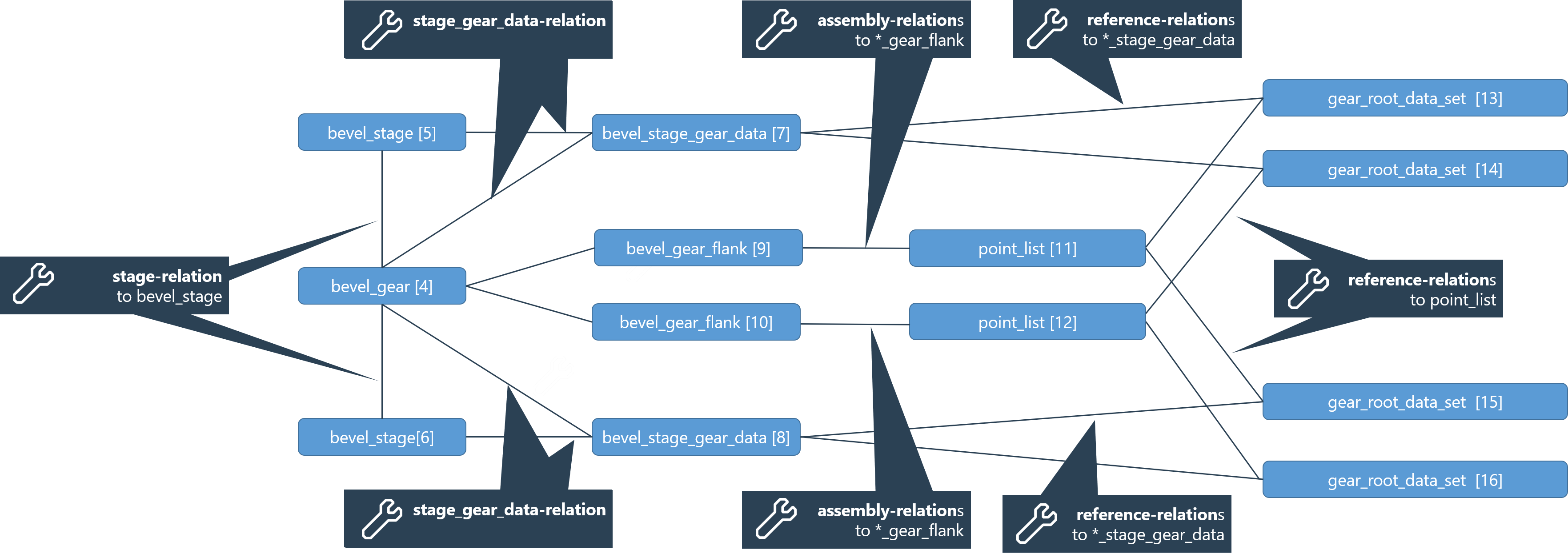

Use case: 3D tooth contact analysis

In the 3D tooth contact analysis, the flanks of two gears are rolled against each other. The associated calculation points are points on the contact lines of the gears for different meshing positions. Therefore, a contact point on one tooth flank always has a corresponding contact point on the other tooth flank.

|  |  |

Overview of the modeling concept, using a bevel gear stage as an example. The process is similar for cylindrical and worm gear stages.

The contact points are defined in the associated gear coordinate system and assigned to the *stage_gear_data component. A contact point on one tooth flank always has a corresponding contact point on the other tooth flank. To reflect this relationship, the same point ID is used for the two associated contact points in the corresponding point list. The contact lines can be identified via the element list. This is assigned to both point lists via a reference relation.

Results data related to the two contact points (e.g., contact depth/gap size or associated local pressure) are stored in the meshing_contact_stage_data_set component. This is linked to both point lists via reference relations. On the other hand, gear-specific results (e.g., the resulting local safety against pitting) are stored in the two meshing_contact_gear_data_set components.

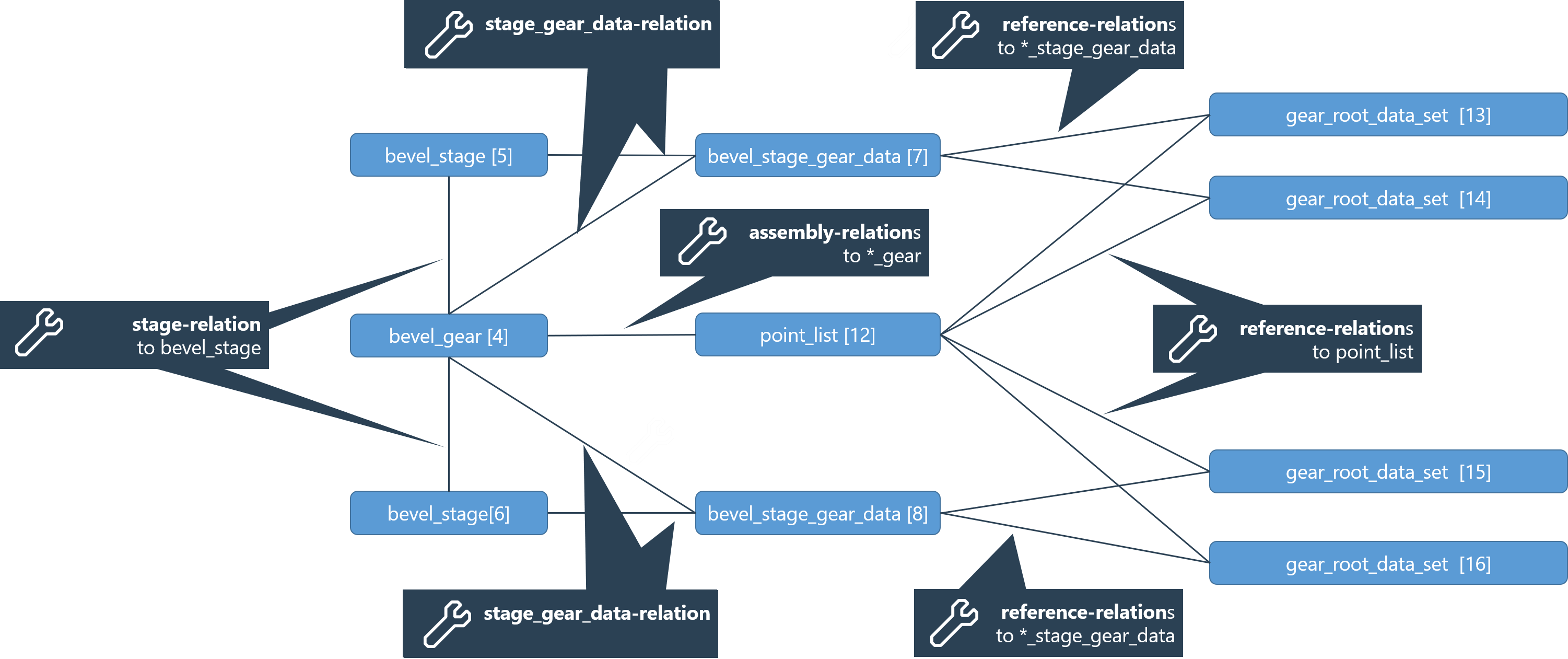

Use case: 3D tooth root data

In addition to detailed consideration of the tooth flank geometry, the tooth root geometry is also often of interest. This can either be in a separate point cloud/mesh structure or, together with the flank, can represent a complete tooth or tooth gap. For a point cloud that only describes a tooth root, it should be assigned to a *_gear_flank via an assembly relation; the points are relative to the coordinate system of the corresponding gear. On the other hand, a mesh of the entire tooth or tooth gap should be assigned directly to the *_gear via an assembly relation.

A local analysis of the tooth root stresses and load capacity is often performed based on the results of a tooth contact analysis. The associated data are relative to points in the tooth root and are generated by loading a mesh. The parameters can be represented by a tooth root data component (gear_root_data_set) which is linked with the point list and the corresponding *_stage_gear_data components via reference relations. If the data for the left and right root are to be represented separately, two tooth root data components should be created for each *_stage_gear_data component.

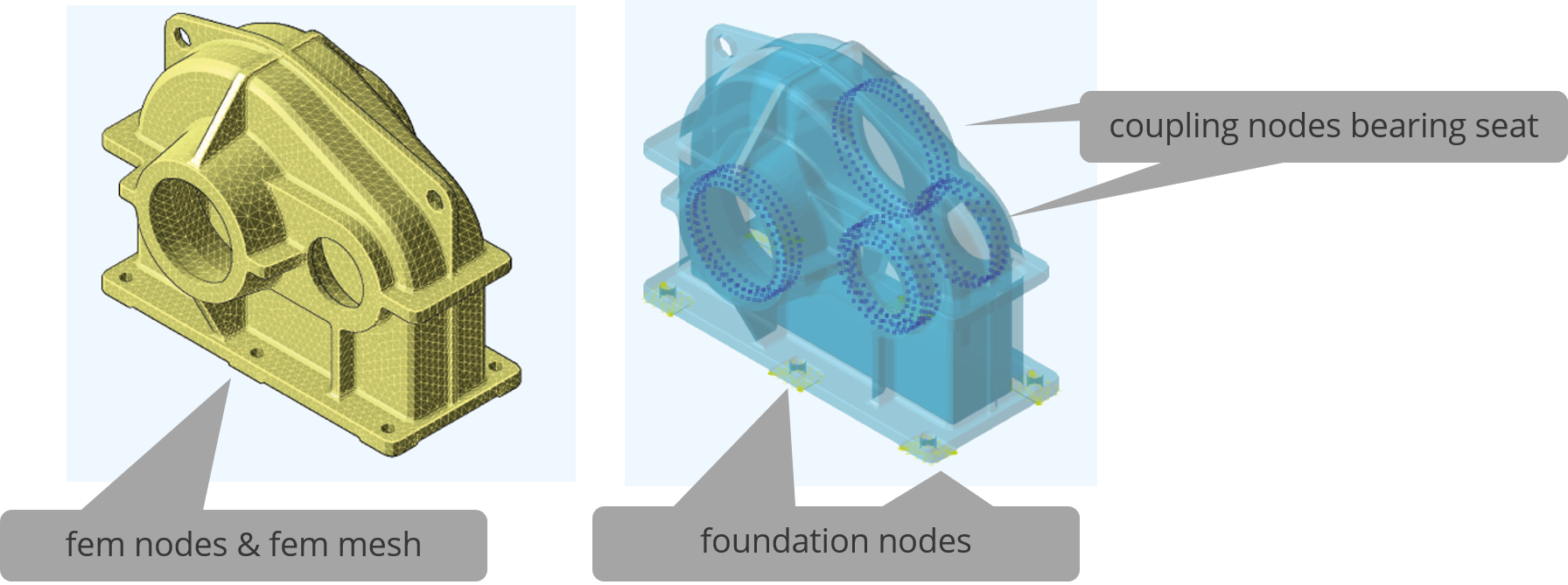

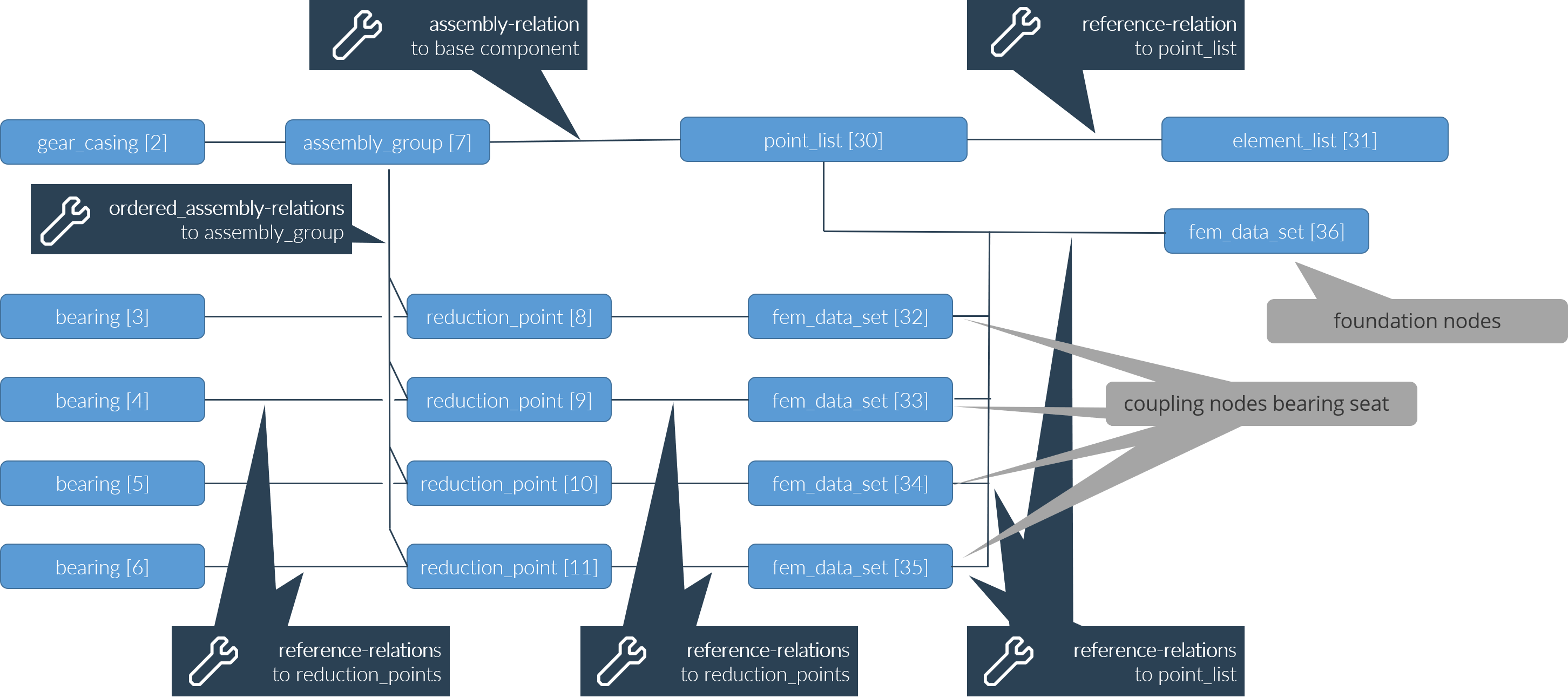

Use case: FE casing with reduced stiffness

Reduced FE stiffness can already be considered in REXS via modeling assembly groups. However, the associated FE data can now also be explicitly modeled in REXS.

The nodes of the FE mesh are stored in the point list. These are assigned to the assembly via an assembly relation and use its coordinate system. The structure of the FE elements can be represented by an element list. For an FE casing with reduced stiffness, the coupling nodes of the reduction points in the bearing seats and the foundation nodes must also be identified. This can be done using fem_data_set components.

Use case: FE planet carrier/FE shaft with reduced stiffness

FE planet carriers or shafts can also be modeled similar to FE casings with reduced stiffness. Here, the fem_data_set for the foundation nodes is omitted.